- Telephone: +39.02.968.2360 E-mail: contattishop@mariodimaio.com

- Fax: +39.02.968.9700 E-mail: contattishop@mariodimaio.com

English

English

-

English

English

-

Italiano

Italiano

My Account

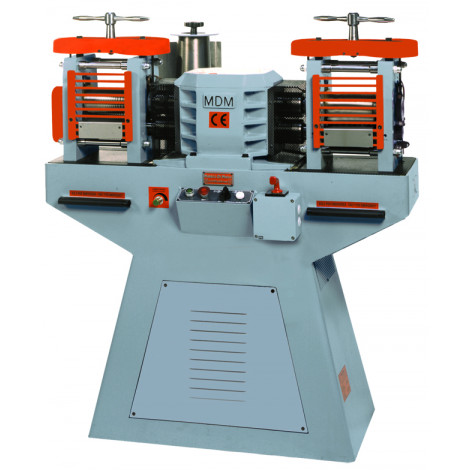

Rolling Mill For Strip With Power Spindles

L613100

Rolling mill for strip with power spindles. Field of application: is ideal for small workshops as well as industrial production (continuos and non-continuos production). Type: the configuration is two-high reversible rolling mills for strip (with reels) is used for strip continuous rolling. Structure: the structure of the rolling mill is a sturdy electro-welded steel frame with double coat baking painting.The cylinders uprights are obtained from spheroidal cast iron. Cylinders: the cylinders are made of special alloy steel with a grinded surface hardness 64 HRC with internal water-cooling system with rotating joints. On request it is possible to supply cylinders with mirror finish, hard chromium plating, Widia® hard-facing. Cylinders bearings: the bearings are mounted on mobile guides, they are heavy duty bronze plain bearings and are provided with automatic closed circuit pressure lubrication with oil recovery and watercooled circuit. Cylinders displacement: manual displacement by hand wheel. Cylinders drive: by means of mechanical homo-kinetic universal joint. Reduction gear unit: the rolling mills have a reduction unit made of helicoidal steel gears with oil bath lubrication. The electric motor drives the reduction gear throught amechanical joint. Drive: the rolling mills are driven by a one-speed electric motor. Reels: Rolling mill is provided with pair of reversible hydrostatic winders. Safety devices: safety devices are provided (in conformity with the international laws in force – EC seal of approval), including: mechanical grids for cylinders, pneumatic barriers for emergency stop. Standard accessories: rolling mill come equipped with hand adjustable press for strip on entry side to the cylinders. Optional accessories: the rolling mills can also be equipped with cooling water pump for cylinders and bearings and felt-covered bars for cylinders cleaning. Technical Specifications: - Cylinder width = 160 mm - Cylinder diameter = 118 mm - Max. cylinder opening = 48 mm - Rolling speed = 8,3 m/min - Max. rolling torque = 318 kgm - Max. rolling pressure = 40 ton - Motor power = 7,5 kW 2x0,75 kW 2 pcs. motorised coilers - Voltage = 230/400V, 3~ 50/60 Hz - Weight = 1200 Kg

)