- Telephone: +39.02.968.2360 E-mail: contattishop@mariodimaio.com

- Fax: +39.02.968.9700 E-mail: contattishop@mariodimaio.com

English

English

-

English

English

-

Italiano

Italiano

My Account

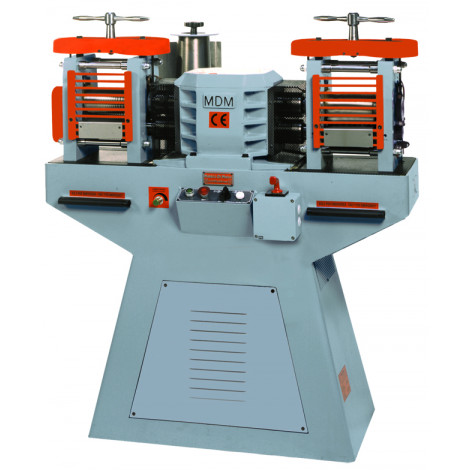

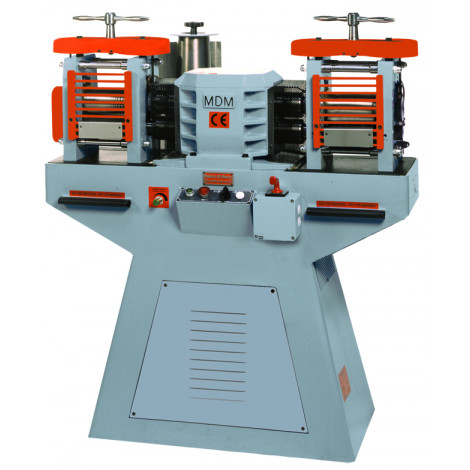

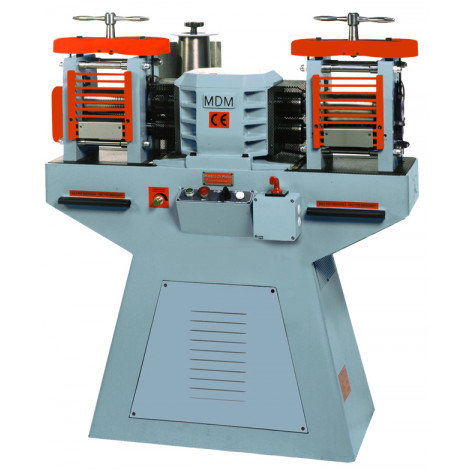

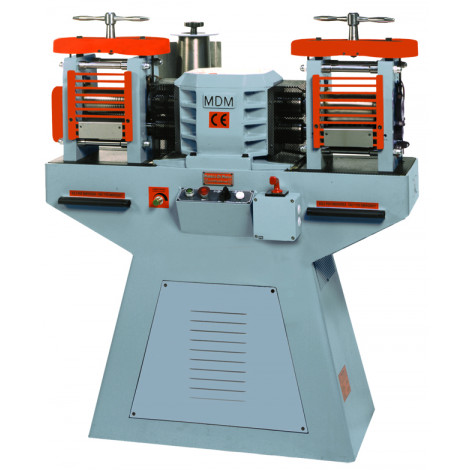

MDM Rolling Mill For Plate

L309100

Rolling mill for plate 220 x 127. Is ideal for small workshops as well as industrial production (continuos and non-continuos production). Type: the configurations is plate roughing mills and is used for plate & wire rough-rolling and finishing. Structure: the structure of the rolling mill is a sturdy electro-welded steel frame with double coat baking painting. The cylinders uprights are obtained from spheroidal cast iron. Cylinders: the cylinders are made of special alloy steel with a grinded surface hardness 64 HRC (plate cylinders). Cylinders bearings: the bearings are mounted on mobile guides, they are heavy duty bronze plain bearings and are provided with automatic closed circuit pressure lubrication with oil recovery and water-cooled circuit. Cylinders displacement: manual displacement by hand wheel. Reduction gear unit: the rolling mill have a reduction unit made of helicoidal steel gears with oil bath lubrication. The electric motor drives the reduction gear throught amechanical joint. Drive: the rolling mill is driven by a one-speed electric motor. On board there is a control panel that includes all devices of maneuver and control. On request a drive with electronic variable speed throught inverter vectorial is available. Reels: available, on request reversible hydrostatic strip winder; horizontal motorized wire winder; horizontal idle decolier for strip. Safety devices: safety devices are provided (in conformity with the international laws in force – EC seal of approval), including: mechanical grids for cylinders, pneumatic barriers for emergency stop. Optional accessories: the rolling mill can also be equipped with a series of accessories chosen according to production needs. We can provide spray lubrication system for plates. Technical Specifications: - Cylinder width = 220 mm - Cylinder diameter = 127 mm - Max. cylinder opening = 40 mm - Rolling speed = 9,0 m/min - Max. rolling torque = 322 kgm - Max. rolling pressure = 52 ton - Motor power = 9 kW - Voltage = 230/400V, 3~ 50/60 Hz - Weight = 980 Kg

)