- Telephone: +39.02.968.2360 E-mail: contattishop@mariodimaio.com

- Fax: +39.02.968.9700 E-mail: contattishop@mariodimaio.com

English

English

-

English

English

-

Italiano

Italiano

My Account

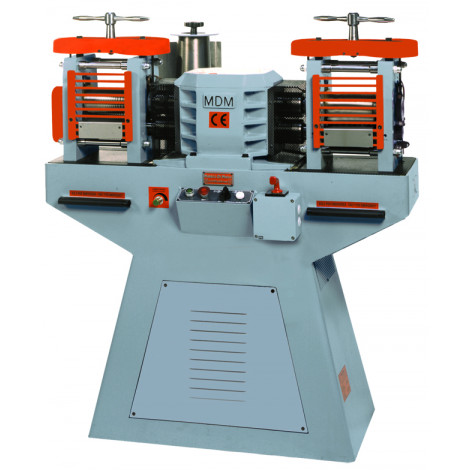

Rolling Mill For Band And For Wire Flattening

L542100

Rolling mill for band and for wire flattening on bronze bushings, one coiler with winding unit. Field of application: LSF 120 x 40 models rolling mill is ideal for small workshops as well as industrial production (continuos and non-continuos production). Type: the configuration is high precision wire-flattening rolling mill. Use: LSF is used for rolling rectangular strip from round wire. Structure: the structure of the rolling mill is a sturdy electro-welded steel frame with double coat baking painting. The cylinders uprights are obtained from steel plates. Cylinders: the cylinders are made of special steel with fitted with Widia® ring with high surface hardness = 1700 HV. Rolls have internal water-cooling system through rotating joints. Cylinders bearings: LSF model have bearings mounted on mobile guides, they are heavy duty bronze plain bearings. Cylinders displacement: manual displacement by adjusting screws and wheel with reading of the opening through mechanical numerator (precision ± 0,01 mm)Cylinders drive: by means of mechanical homo-kinetic Oldham coupling controlled by a splitter with helicoidal steel gears with oil bath lubrication. The transmission from the motor reducer to the splitter is through chain. Drive: the rolling mills are driven by an electric motor with speed variation controlled by a vectorial inverter On board there is a control panel that includes all devices of maneuver and control. Reels: LSF model come equipped with horizontal motorized coiler with winding unit (with adjustable translation, pitch and shooting) and vertical idle decoiler for wireSafety devices: safety devices are provided (in conformity with the international laws in force – EC seal of approval), including: mechanical covers preventing acces to parts in motion, push-button for emergency stop. Optional accessories: the rolling mill can also be equipped with spray lubrication system for wire; a linear counter for rolled wire; felt-covered bars for cylinders cleaning. Technical Specifications: - Rolls width = 40 mm - Widia rolls diameter (LW) = 24 mm - Rolls diameter = 120 mm - Thickness to be rolled = 4 ÷ 0,05 mm - Rolling speed = 0 ÷ 40 m/min - Max. rolling torque = 20 kgm - Max. rolling pressure = 5 ton - Motor power = 2,2 kW 1 x 0,68 kW Motorized windin reel - Voltage = 230/400 V, 3~ 50/60 Hz - Weight = 480 Kg

)