- Telephone: +39.02.968.2360 E-mail: contattishop@mariodimaio.com

- Fax: +39.02.968.9700 E-mail: contattishop@mariodimaio.com

English

English

-

English

English

-

Italiano

Italiano

My Account

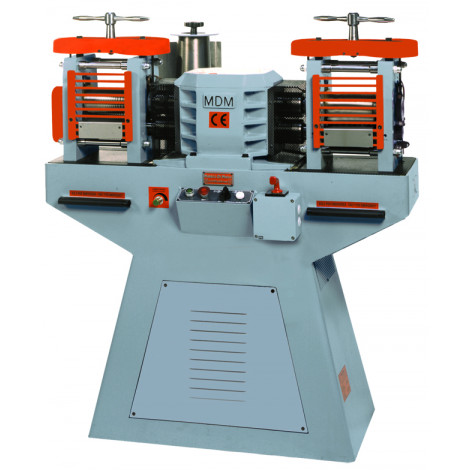

MDM GL 200 Rolling Mill

L231100

GL 200 Rolling Mill

Plate and wire rolling mill

The structure of the rolling mill is a sturdy electro-welded steel frame with double coat baking painting. The cylinders uprights are obtained from spheroidal cast iron.

The cylinders are made of special alloy steel with a grinded surface hardness 64 HRC (plate cylinders), 61 HRC (wire cylinders). On request it is possible to supply plate cylinders with mirror finish,

hard chromium plating, internal water-cooling system with rotating joints.

The bearings are mounted on mobile guides, they are heavy duty bronze plain bearings and are provided with automatic closed circuit pressure lubrication with oil recovery (water-cooled circuit on request ).

Cylinders displacement: manual displacement by hand wheel.

Cylinders drive: by means of mechanical homo-kinetic Oldham coupling.

Reduction gear unit: the rolling mill have a reduction unit made of helicoidal steel gears with oil bath lubrication. The electric motor drives the reduction gear throught amechanical joint.

Drive: the rolling mill is driven by a one-speed electric motor. On board there is a control panel that includes all devices of maneuver and control. On request a drive with electronic variable speed through inverter vectorial is available.

Technical Specifications:

- Cylinder width = 200 mm

- Cylinder diameter = 105 mm - 110 mm

- Max. cylinder opening = 35 mm

- Rolling speed = 7,5 m/min

*Available on request drive with variable speed throught inverter

- Max. rolling torque = 228 kgm

- Max. rolling pressure = 38 ton

- Motor power = 5,5 kW

- Voltage = 230/400 V, 3~ 50/60 Hz

)