- Telephone: +39.02.968.2360 E-mail: contattishop@mariodimaio.com

- Fax: +39.02.968.9700 E-mail: contattishop@mariodimaio.com

English

English

-

English

English

-

Italiano

Italiano

My Account

Orlatrice PN

P681100

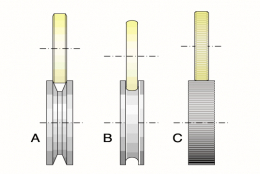

This machine was designed to prepare blanks for pressing. Thanks to the combination of three types of shaped rollers (interchangeable), a single machine can work in several different ways: - drawing of the disk for precise housing in the coining die (3 “A” rollers) - elimination of blanking burrs (3 “A” rollers) or (2 “B” rollers + 1 “A” roller) - hardening of the disk edge for better finishing of the knurled rim (2 “B” rollers + 1 “A” roller) - knurling of the disk rim (2 “A” rollers + 1 “C” roller) - blank edge striping (2 rollers “A” + 1 roller”C”) The two bottom rollers are powered by a ratiomotor connected to an electric motor (with foot pedal). The top roller is driven by a mobile slide (with an automatic pneumatic drive), which is powered by a pressure lever, and it has an adjustable mechanically controlled stop device. Technical Specifications: Productivity = 180 pieces/h Disk dimensions = ø 50 x 3,5 mm (max) Absorbed power = 160 W Air supply = 6 bar Power supply = 400V, 3~, 50/60 Hz

)