- Telephone: +39.02.968.2360 E-mail: contattishop@mariodimaio.com

- Fax: +39.02.968.9700 E-mail: contattishop@mariodimaio.com

English

English

-

English

English

-

Italiano

Italiano

icon cart

0 Items - 0,00 €-

MDM Magnetoclean Tumblers

Field of application: Magnetic tumbler for small non ferrous part and precious objects. The tumbler applies a rotating magnetic field to a group of tiny steel needles (inserts of various shapes)

availability -

H38-2 MDM Rotating Tumblers

MDM Rotating Tumbler with cage (CE). Wet tumbling of small metal parts and precious objects: according to the different abrasive materials employed, these machines can be used for grinding, smoothing

0,00 €availability -

Otec Dry Polishing Container

Container of 6 litre for dry tumbling (polishing), work cycle 2 ÷ 3 h. Very fine polishing granulates made from walnut shell provides gentle removal in the micro range. ECO-Maxi achieves: - Very

Out of stock -

Otec Wet Grinding

Container of 6 litre. With wet grinding, the workpieces move through the process container in a toroidal current. The difference in mass between the workpieces and the plastic abrasive causes material

Out of stock -

Otec Magnetic Polishing

Container of 6 litre. Magnetic polishing is the ideal preparatory stage for wet finishing and replaces the traditional electrolytic polishing bath. With this mechanical polishing process, tiny steel

Out of stock -

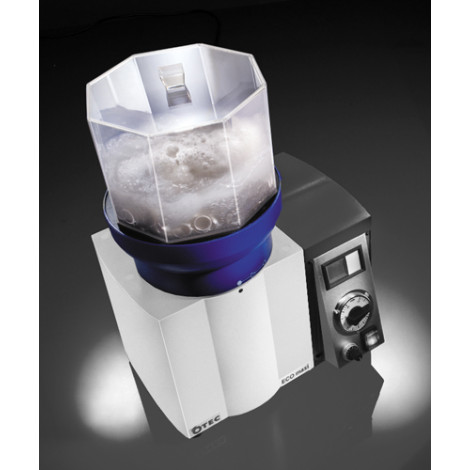

Eco-Maxi Basic Unit

Eco-Maxi basic unit for three tumbling methods (magnetic, wet and dry). Provided with a seat for rapid fitting of containers (not included, see cod. H469810, H469820 and H469830), complete with timer

Out of stock -

Eco-Mini Dry Tumbler

"ECO-mini Dry" dry centrifugal tumbler. Applications: Dry cleaning a polishing of metallic and precious objects. Especially suitable for repaired objects, restoration of displayed articles, samples,

Out of stock -

Eco-Mini Wet Tumbler

Applications: wet deburring, grinding and smoothing of metallic and precious objects. Especially suitable for objects with extremely deteriorated surfaces or rough casts. Features: Single-block

Out of stock -

Magnetic Tumbler 400

Magnetic tumbler for small non ferrous parts and precious objects. The tumbler applies a rotating magnetic field to a group of tiny steel needles (inserts of various shapes) placed in a container

Out of stock